By Dr. Amornrat Limmanee, Solar Photovoltaic Team Leader of Solar Photovoltaic Research Team,Energy Innovation Research Group of ENTEC Interviewed by Dr. Buncha Thanaboonsombut Article by Mrs. Orawan Sumriddetkajorn

Q: Could you tell us about your educational background? We have known that you studied high school in Japan, right?

A:

After I graduated from junior high school in Thailand, I won a government scholarship to study in Japan for one year. Later, I continued to study high school until I graduated with a Ph.D. in physical electronics, totaling 13 years in Japan.

I have always had a passion for science and mathematics, therefore studying in Japan was a great opportunity since Japan is one the most advanced countries in the world in electronics technology. I, thus, chose to study electrical engineering.

Q: Why did you choose to study in depth about solar cells during your master’s-doctoral degree?

A:

Q: During a Ph.D study, what was your research topic? And which private company did you take an internship?

A:

My research topic was the development of a film layer in a crystalline silicon cell, which was an anti-reflection layer and reduces energy loss on the bottom and top electrodes by forming silicon nitride. Since solar cells require a lot of refraction, the top layer must be developed to reduce reflection and reduce other losses, therefore, I had developed silicon nitride film and silicon-oxide to be used in crystalline silicon cell structures.

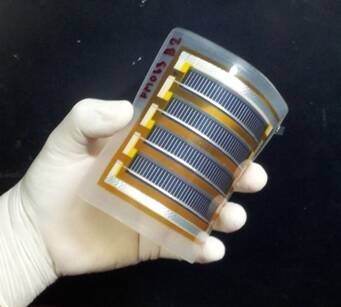

During the internship, I worked at Mitsubishi Electric Corporation, where I learned about doing research and development of small cells, measurement and analysis of small cells and the actual fabricatiom process to create commercial solar panels.

Furthermore, subsidiary companies of Mitsubishi Electric not only produce various electrical and electronic devices but also have their own solar cell plantsl; however, most of them are sold within Japan and exported to countries other than Thailand. At that time, the company measured the properties of silicon wafers to determine which wafers would be suitable for building solar cells, as well as the selection and analysis method of how to achieve high efficiency and reduced loss.

Q: Since Japan has a strong reputation for the production of electronic devices and solar cells. If we consider global picture, is there any particular country to compete with Japan?

A:

Q: When talking about solar cells, people usually think of black panels installed on the roof or on the ground. Could you give us an overview of solar photovoltaic technology and what does a solar cell consist of?

A:

A solar cell l is a semiconductor with energy band gaps that directly absorb the solar spectrum. There are various types of solar cells, but the most common is fabricated from silicon for its affordable prices and large quantities. However, some types are rare, e.g., those made for rare earth, which is expensive and has high production cost. The doped material creates a potential difference in the PN junction, the photon [1] creates the negatively charged electron and the positively charged hole, both of them could conduct electricity. A potential difference, therefore, causes the electrons to move in the opposite direction of the hole, and when a circuit is complete, electricity is generated.

[1] A photon is a particle of light and its energy depends on the wavelength of the light.

Q: How does the solar cell work? Does the research team view light as a wave or a particle?

A:

It can be viewed both ways. If we talk about an electron and a hole, then we consider light as particles because, in solar cell measurements, one need to measure quantum efficiency [2] to see how much light is converted into electricity at each wavelength. On the contrary, if we consider light as wave, the amount of light energy per square meter before conversion will be of interest in order to see the whole picture.

[2] quantum efficiency is the amount of electrons that the materials emitted per amount of photon absorbed.

Q: What are the main components of a solar cell system?

A:

- A solar panel

It is a combination of cells connected to give the voltage and current required for the system.

- An Inverter

This device is used with home appliances to convert direct current to alternating current because solar cells yield a direct current.

- A battery

This device is required to store electrical energy produced from solar cells.

- A charge controller

This device is necessary because the electricity produced from the solar cell may be irregular depending on the amount of sunlight; thus, it could damage the battery if charged directly.

Q: If we talk about solar cells, it is a material that receives light and then converts into electricity. But if we look at the whole system, Is it called a solar photovoltaic system?

A:

Yes, it is. Actually, there is another form of solar power generation, which is called a solar thermal to produce hot water or steam and then to generate electricity. However, if converted from light to direct electricity, it is called a solar photovoltaic system or solar PV system.

Q: From the point of view of materials that refer to different types of crystals such as monocrystalline, polycrystalline or multicrystalline, and amorphous, how do these crystals affect the difference in photovoltaic performance?

A:

The most efficient photovoltaic crystals are single crystals because they are homogeneous. However, if it is polycrystalline, there will be grain boundaries, which cause a lost in energy. In the past, single crystal was quite expensive, therefore, polycrystallines are widely employed, even though with lower efficiency. But in economic terms, they are cost-effective.

At present, China’s large-scale production of single crystals has caused the price of single crystals to plummet, thus making single crystals dominates the market. About 96% of silicon wafers used in the solar cell industry are made in China, allowing China to control both from upstream to downstream and causing a price reduction since 2010. The price per watt of solar cells was once as high as 80 baht per watt, but now it’s now reduced to only 20 baht per watt. At the solar farm level the cost is lower than 10 baht per watt. Thus the cost of solar energy is lower due to decrease panel prices. In other words, other countries cannot lower prices as much as China because China is a wafer producer, and once it is sold, China is able to fully control both price and quality.

Q: How competive is amorphous silicon thin film technology?

A:

Q: If the demand for amorphous silicon decreases, will its research and development continue or decrease following the trend of the market?

A:

Q: While you were working at NECTEC, what was your research?

A:

Q: When the crystal price decreases, how do the research direction respond?

A:

Well, during that time, I had the opportunity to attend a solar panel performance analysis and reliability training at AIST (The National Institute of Advanced Industrial Science and Technology) in Japan, which was considered to be one of the three largest solar cell testing centers in the world. I had learned about the optical spectrum measurement as it affects the efficiency of each type of cell, e.g., this type of cell may work properly in Germany but not in Japan. There are also other factors such as temperature, as well as the measurements needed in the laboratory, the standard and tools for the measurement that is a practical panel to be used outside.

Q: For an outdoor solar panels, there will be meteorological factors such as cloud cover and wind blowing, what are the important factors that need to be taken into account?

A:

The first important factor is light intensity and the second is panel temperature because the standard conditions are measured at a light intensity of 1000 W/m2 and a panel temperature of 25°C to assess the panel’s power capacity. In Thailand, the idle temperature of the panel is 30 °C when exposed to light; however, the temperature will rise even more especially in April, which can reach 70°C. And if the solar panel is installed on the roof, which has poor ventilation and can reach temperatures up to 80 °C. Although solar cells have a strong preference for light, they dislike heat.

Q: What is the optimum condition for a single-crystal solar cell?

A:

The ideal conditions are high light intensity with low temperature, which can be found in some European countries. However, in the equatorial tropics, there is a lot of light throughout the year, the advantage is the maximum exposure to light, but at the same time, there might be some losses caused by relatively high temperatures as well.

Q: As for the dark color of the solar cell, is there an academic reason for this?

A:

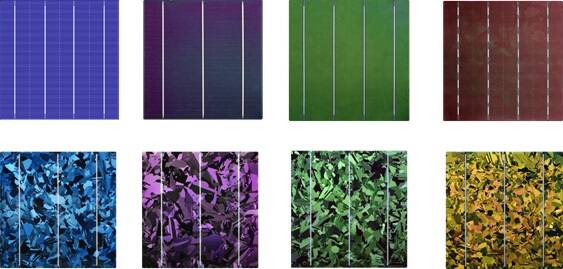

The dark colors absorb all components of white light. The fact that we see a color means that it is reflected to our eyes, i.e. that color is not absorbed. For example, the silicon appears dark blue since it reflects dark blue color and absorbs other colors. In fact, 40 percent of the solar energy is in white light with wavelengths ranging from 400-800 nm.

We can adjust the color of solar cells for aesthetic purposes. For crystalline silicon cells, the silicon nitride at the top anti-reflective layer could be manipulated by adjusting the refractive index and film thickness. It is possible to obtain various colors such as yellow, ocher, or others , but the efficiency of the panel will be reduced because it can absorb less colors.

As a result, research in BIPV (Building Integrated Photovoltaic) makes it possible to choose what color of cell is needed or what color of glasses. However, this is done without placing importance on efficiency, but mainly focus on the beauty decoration.

Q: In theory, what is the highest efficiency can a solar cell achieve?

A:

For a light-concentrating cell, which employs lens to increase light intensity, the efficiency is close to 50%. Some reports have claimed that this type of cell can have an efficiency of 49-50%. But if you read the details and test conditions, you will find that it is a concentrating cell with 300 suns. The general light is equivalent to 1 sun. That is to say, this type of cell concentrates the light intensity at the focused area point and measures its efficiency at this point, in which this condition does not occur naturally, but can occur in theory or in a controlled environment. However, in reality, its performance cannot be achieved because there are meteorological factors involved.

Q: How much is the efficiency in practice?

A:

For conventional silicon cells, the efficiency would be around 20%, but for the panel efficiency used in current solar farms, the efficiency would be around 18-19%.

Are there any technological possibilities that will boost the efficiency?

A:

In terms of the efficiency of silicon cells, it is possible to achieve 25-26% but with higher cost. Therefore, people will not invest in solar farms with the most efficient panels, but they will consider the cost-effectiveness of the investment. From an economic point of view, it is preferable to achieve higher efficiency is achieved with less space. The low-efficiency panels can produce the same amount of electricity, but more space is required.

Q: We have heard of solar cell technology for quite a long time. Some scholars have proposed to that a significant number of Thai people could produce electricity on their own and connect it to the grid system; however, solar cells are still use only in some houses and not widely adopted. What obstacles are there?

A:

The reason why solar cell technology is not widely used is because it is an unstable power generation system. That is, the electricity produced changes depending on the weather. Moreover, the system can’t generate electricity during the night, whereas power plants can be operated and controlled for 24 hours. Therefore, the system must be ready, e.g., by using batteries to store power, but this will increase the cost. Thus, solar cell technology is not suitable to be used as the main power generation system.

However, for a small system, people should be educated first about the capability of solar cell technology since there is a misunderstanding that it can meet the need for electricity of the whole house. In reality, it only helps reduce the amount of electricity used. That is to say, the electricity produced from solar cells can be used with some electrical appliances such as fans and lights, but it is not suitable for use with certain appliances such as air conditioners, irons or ovens. Furthermore, the price of a small system may not be cheap because the system must have an inverter and a panel and there is an installation cost. The house owner, therefore, needs to be prepared for the total expense and documents to inform the electricity authority.

Q: For a big picture of Thailand, is there a policy that would increase the proportion of electricity produced from solar cells?

A:

Yes, there is, but the focus is on promoting installation on the roof and floating solar platform, including installation on the roof of houses, factory roofs, and warehouse roofs, which will not disturb the agricultural land by using the existing building space that is supported by the government. However, recently it has been installed on the roofs of warehouses, as well as medium and large factories due to readiness in investment. For these enterprises, if the electricity can be sold and the peak load is reduced during the day time, the electricity cost will be reduced and achieve a break-even point relatively faster.

For a floating solar-cell platform, which is a new trend around the world, the water surface areas, such as seas, lakes, dams are utilized by attaching solar cells to the buoys. Since the buoys are floating on the water surface, the panel temperature will be cooler because of its proximity to the water and exposure to the wind.

At present, Thailand has already begun the installation of floating solar-cell platform at the Sirindhorn Dam of the Electricity Generating Authority (EGAT) with 45 megawatts of actual usage. On the contrary, long-term studies are required because the panel is exposed to moisture all the time, which can cause the electronics to deteriorate, and if the system is installed near the sea, the salt vapor will eventually cause corrosion on the panel and the wires.

Q: How long do solar panel last?

A:

If the panel has a warranty of about 20-25 years, its performance will deteriorate at least 80% from the beginning. However, in the humid tropics, it will deteriorate faster, therefore, its lifespan will not reach 20 years. The cost-effective period for a large system is about 7 years, but for a small system for home, it’s about 10 years (depending on the size of the system, equipment price, electricity price, and earned incentives). Even if the solar cell deteriorates, it can still generate electricity and the first equipment that deteriorates is likely an inverter.

Q: What proportion of the inverter price compare that of the whole system?

A:

About 10 percent or about ten thousand Bath. So this is not a problem for a factory, but is quite a concern for houses.

Q: How to manage expired or low-performing panel endpoints?

A:

In foreign countries, there are recycling plants for solar panel. These plants separate each part and reuse some parts, but the cost of recycling is very high since the process requires a large amount of energy and chemicals. Studies indicated that recycling solar panels is not cost-effective, therefore, reuse is preferable.

In Thailand, there is no recycling plant and no reuse mechanism, but it is under development. At present, we have installed no less than 3 gigawatts of panels in the system, or have at least 12 million panels. In the next 2 decades, we will have more than 40 million panels, therefore, the systematic end-of-use management will be crucial to indicate whether solar cells are good for the environment or not.

Q: In highly developed countries, such as Japan, Germany or other countries in Europe, how do they deal with the expired cells?

A:

They collect the expired cells back for recycling, e.g., in Europe where everything from glass, silicon, electrodes, and precious metals can be recycled. However, it may not be cost-effective at this point, but technically it can be done. Thus, disassembling-and-crushing for landfill has become the most popular method, in which Thailand also mainly uses this method.

Q: Would you tell us about your work experience on a policy related to the use of solar cells?

A:

I had an opportunity to contribute to Thailand’s first report on the state of solar cells in the country about 10 years ago, as well as promoted reuse or recycling. The Ministry of Higher Education, Science, Research and Innovation had cooperated with the Ministry of Industry to create a fully generated support mechanism after the solar farm has dismantled the panels by ensuring what should be done with the panels before they are distributed without being traced back.

At present, some solar farms replace solar panels before their lifetime of 20 years. They do this because the energy produced was reduced once the solar panels deteriote and by replacing them with new ones, they can maintain their status of power-generating enterprises.

However, some of the replaced panels were kept, some were resold, or some were donated, which we could not be certain of the end objective of the collecting and managing processes.

Q: Your status report done 10 years ago must have had a forecast on the future. How does the forecast compared with the actual situation now?

A:

The expectation from 10 years ago and the present is consistent on the growth of number of panels. Therefore, the management is important as we talked about panel recycling 10 years ago, but at that time, it was still considered to be 20-25 years longer. Since 2010, there has been recycling research, but it’s not stressed that much because Thailand emphasizes on promoting the installation for use on land, roof or floating platforms. However, ultimately all panels must go through the process of management and recycling, or discarding, which creates the concern when a foreign country dismantles the panel, whether it will be sent to Thailand like an electronic device or not.

Q: What is your proud achievement?

A:

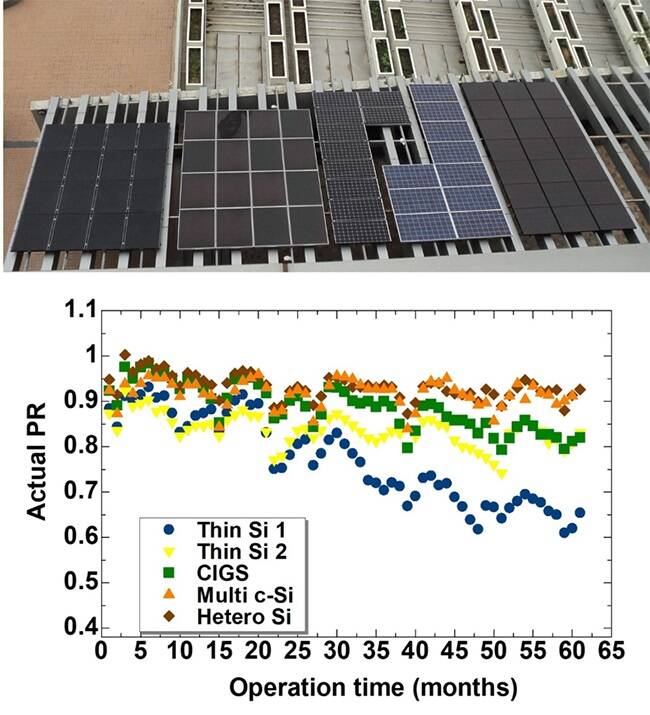

My proud achievement was the part of the testing and characterization from 10 years ago because at that time, Thailand only focused on the installation, not the testing and characterization, which was also an important part. As for reliability, our believe is based on foreign claims. Ten years ago, I had an opportunity to study the reliability performance of five cell types in the tropical areas, in which this research work had also received an award because other countries, such as Japan, Germany, and the United States are not the countries in the humid tropics. Therefore, Thailand is the first country to present this research by showing the existing standards do not meet the actual use in our country as Thailand is hot and humid, as well as the UV is stronger than those countries. Thus we had to do some more tests for reliable results.

On the contrary, at present, India and Singapore have recently started to do this kind of research. For example, Singapore has brought a research team from Germany to help them, therefore its research has been developed very fast. Although Singapore does not possess land to intall the solar panels, the country is focusing on the testing and analysis and gathering the information of the tropical areas to create a model.

Q: Can you tell us about a case study that you had helped to solve the problem or developed the system to suit various locations?

A:

Our team had visited the solar farm area, which is a real business sector, to help solve the system problems of the electricity generation, e.g., find out why the electricity produced is reduced. Another part was the areas that are inaccessible to electricity, the team had to design a practical solar cell system to meet the amount of electricity required, or if they have a hydro power, we had to find a way to integrate it with solar cells to make a hybrid system. Furthermore, in each season, the amount of sunlight is different, therefore, the use of solar cells in each area does have its own characteristics.

Q: What aspects of the progress are expected to emerge related to the use of solar cells in our home or in the world?

A:

I want you to mainly focus on the applications of solar cells that are worthwhile and useful. In some aspects, solar cells may not have to be a large system, such as in the agricultural sector where transmission lines are not accessible. That is to say, solar cells can help farmers get electricity by replacing the oil-powered generator, which will have an impact and a high usage value because it is alternative energy for niche markets. Thailand may not be like Japan or Germany as they have a lot of transmission lines. However, Thailand still has areas where electricity is inaccessible, therefore, use of solar cells would be ideal in many cases since it will help save the cost of hauling transmission lines.

Q: Do you have any advice for those who are interested in working on solar cells, which fields should they study or any specific issues?

A:

The development of solar cells requires a lot of knowledge in various fields. For example, solar cells are materials for electronic power but when the cells are put together for resisting the moisture and UV light, engineering knowledge is required. Moreover, creating cells that can follow the sun altitude requires knowledge of motors, preventing dust to help reduce the loss from dust obscuring requires knowledge of coatings, or exposing to the UV light in the actual use, will the coating be deteriorated or how often it will need to be coated requires knowledge of materials, as well as controlling factors to optimize the performance of the inverter requires knowledge from various fields to help enhance the system to be more effective.

Lastly, we would like to thank Dr. Benz for sharing knowledge about solar cells and various ideas. In the future, we would like to invite her to share more of other new research studies of ENTEC.

For those who are interested in this podcast, please visit: